High performance engine building is usually a matter of mixing and matching off-the-shelf components to find a combination that works efficiently. Today’s engine builders, however, are faced with a wider variety of choices and may find it more difficult to achieve optimal performance. With the larger selection of engine blocks and cylinder heads, setting up a precise valvetrain can become a major challenge, especially in unique one-of-a-kind builds.

The Jesel Custom Shop is available to help engine builders struggling with such issues by providing custom designed and manufactured valvetrain components that may be necessary for different block-and-head combinations. Originally launched in 2009, the custom shop has refined its development process over the years. First, customer’s cylinder heads are measured and digitized, and then the data is entered into the shop’s engineering programs.

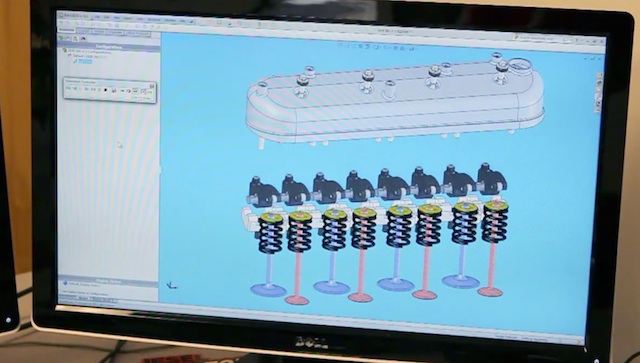

Once a three-dimensional model is created in Solid Works and analyzed with the latest Finite Element Analysis (FEA) software, Jesel engineers virtually design and test new valvetrain components in a very compressed timeframe.

Engineers use those findings to prototype the custom component for further evaluation. After the prototype has been checked and tested, Jesel’s CNC equipment manufactures the new component.

Jesel’s engineering crew uses the latest software to prototype and test components in a cost effective way.

According to Jesel, examples of the Custom Shop’s work are most prominent in some of Detroit’s latest engines.

“The GM LS and Chrysler Hemi are significantly handicapped by a lack of space for a proper high-performance valvetrain,” say officials. “Most stock LS heads can only handle a 1.300-inch diameter valvespring and short rockers that severely limit valve lift. The Custom Shop can modify existing LS heads to accept a 1.550-inch or larger spring that will accommodate valve lifts reaching one-inch.”

By machining the head in house, Jesel can custom fit a longer rocker to clear the spring while adding multiple mounting points to firmly secure the valvetrain. This modification also requires angle milling the valve cover surface and a set of Jesel’s billet aluminum LS valve covers to cover up the new Pro Series rocker system.