With the insane popularity of the LS platform, that’s almost all you hear about these days. Sure the Gen 1 SBC is far from dead (will the SBC really ever die?), but by and large it seems like the LS platform gets the bulk of the small-block Bowtie coverage anymore. Add in the introduction of the direct-injected LT1 platform, and now not only do we have another modern platform getting all the attention, but now we have another new GM platform utilizing a name that has been utilized twice-previously by the General.

So when we saw our friends at Golen Engine Service recently post a dyno video of a classic Gen-II LT1 they built for a customer, it caught our attention. Maybe it’s because the mid-‘90s were some very formative years (automotively speaking) in your author’s life, and an LT1-powered Camaro played a role in that. Or maybe it’s just because a Gen-II LT1 is something different these days.

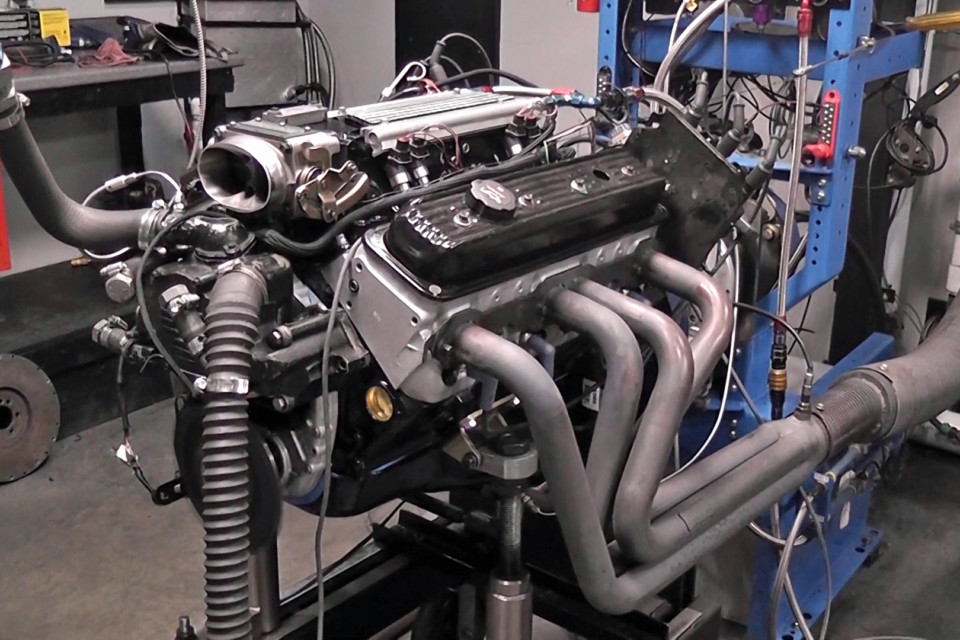

For Golen Engine, the Gen-II LT1 never fell off their radar, and they’ve offered a ready-to-go 383-cube street-oriented budget LT1 package for quite a while. They start off with a seasoned cast-iron factory block, which they bore and deck-plate hone to a 4.030-inch bore. The deck is then machined to match the pistons at zero deck height. Golen then adds aftermarket four-bolt main caps, and line bores and hones the whole assembly.

Into those mains, they drop a Scat Enterprises 9000 series steel 3.750-inch-stroke crankshaft, which is internally balanced front and rear. Attached to the Scat crank is a set of 6.000-inch Scat forged 4340 I-beam rods which have been upgraded with ARP rod bolts.

The Golen 383 LT1 is a relatively simple combination that uses quality components with a track record of working well together in order to make solid power from an engine originally produced during a rather lethargic period in horsepower history.

From there, a set of MAHLE forged 4032 aluminum pistons with Grafal anti-friction coating applied to the skirts are installed. With a dome volume aimed at a 11.5:1 compression ratio, the pistons utilize a standard set of MAHLE Plasma rings. To provide the lifeblood of the engine, Golen utilized a Melling Select Performance oil pump with Melling’s heavy-duty drive. The Melling pickup tube is fitted to the factory oil pan, and then TIG-welded in place to prevent any issues.

Moving to the top end, Golen took a set of factory aluminum LT1 castings and performed a three-angle valve job on them, as well as a stage-two runner and bowl porting process. Then the team installed 2.02-inch stainless Manley Performance intake valves and 1.56-inch stainless exhaust valves, and bolted the head to the short-block with a set of ARP head studs.

A set of 5/16-inch, .083-inch wall pushrods from Smith Brothers ride the Golen-spec camshaft ground by Comp Cams, while Ultra Pro Magnum 1.6:1 rockers actuate the valves themselves. Lunati polished double valvesprings control the valve motion, and lightweight hardened-steel locks and retainers keep the valvesprings in place.

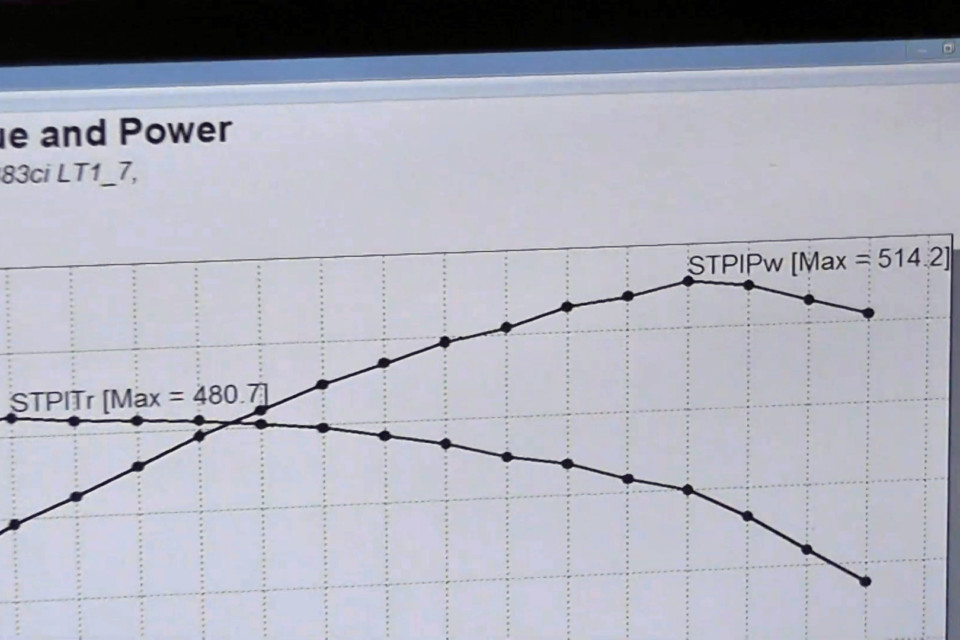

While Golen generally rates this package at 500 horsepower with a 2,300-6,500 rpm powerband, this particular example pushed the dyno to 514 horsepower at 6,000 rpm, with 480 lb-ft of torque at 4,900 rpm through the factory intake manifold and some dyno headers. Not too shabby for a vicenarian engine with some mild aftermarket parts and a warranty.

Delivering on their promise, and then some, this particular engine cranks out 514 horsepower at 6,000 rpm, and 480 lb-ft of torque at 4,900 rpm. Not bad at all when you crunch the numbers and realize that this is a 71-percent increase over the LT1’s highest production power rating of 300 horsepower.