Whether it’s modern muscle or classic Detroit Iron, American-made muscle cars are stiffer, more advanced, and can carve turns with ease now. Track weapons like the GT350R and Camaro ZL1 might offer turn-key exotic-slaying abilities off the dealer showroom floor but today, the suspension and chassis modifications to classic Pro-Touring RestoMod-style cars shows no sign of slowing down either.

The modern tech applied to 50ish-year-old chassis can make them outrun muscle cars of today and BMR Suspension has the gear you need to take anything from the space-age all the way to, y’know, our age.

BMR Suspension, out of Florida, ramps up the suspension and chassis of old muscle cars and is also re-engineering suspension geometry for better performance. Enter their new product, the Control Arm Relocation Brackets for all GM A-Body cars from 1964 to 1972. That iteration of the A-Body includes many GM heavy-hitters like the Chevrolet: Chevelle, Malibu, Monte Carlo, and the Pontiac: Tempest, LeMans, GTO, Grand Prix, as well as the Oldsmobile Cutlass and Buick Skylark.

These Control Arm Relocation Brackets part number CAB400 re-imagine what engineers back then didn’t (or couldn’t). The problem was in the ability of the A-Body suspension to have more anti-squat characteristics by providing ideal suspension geometry for the rear axle control arms. The torque and weight shift translated into a loss of forward energy and weaker hole-shots, so BMR made it happen with a simple do-it-yourself bracket relocation.

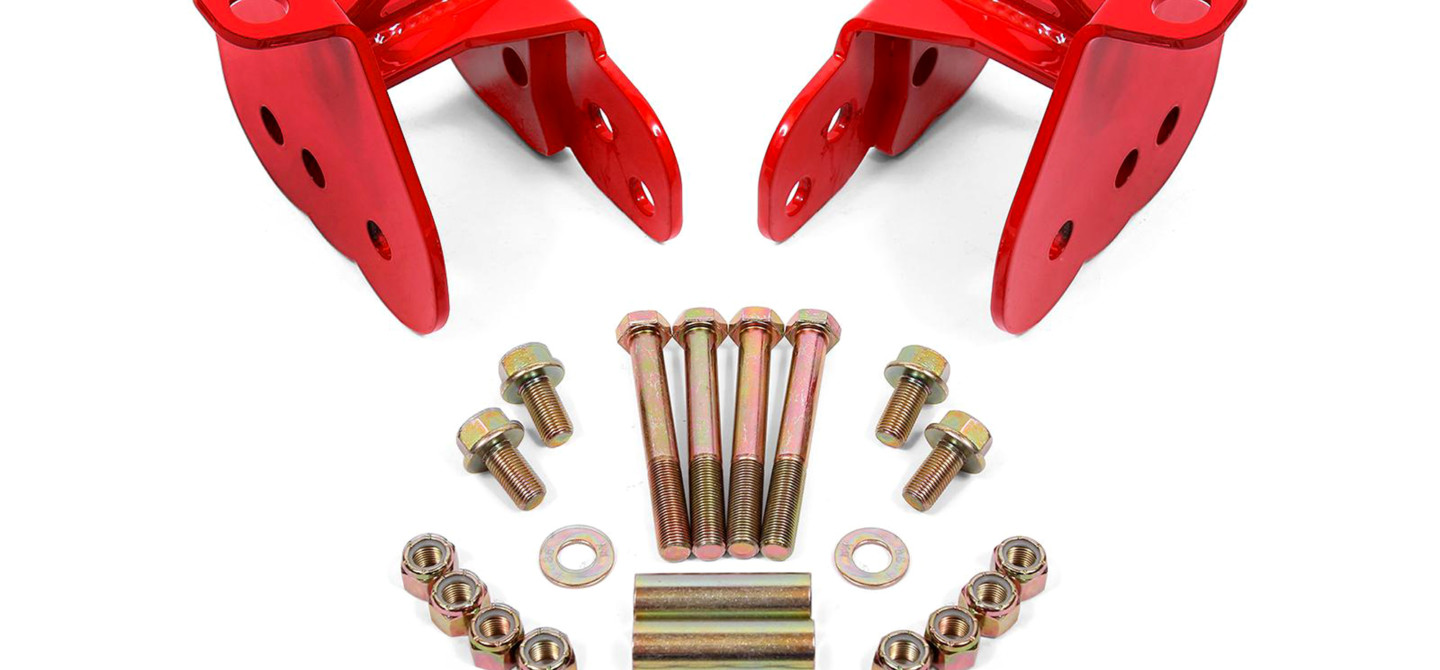

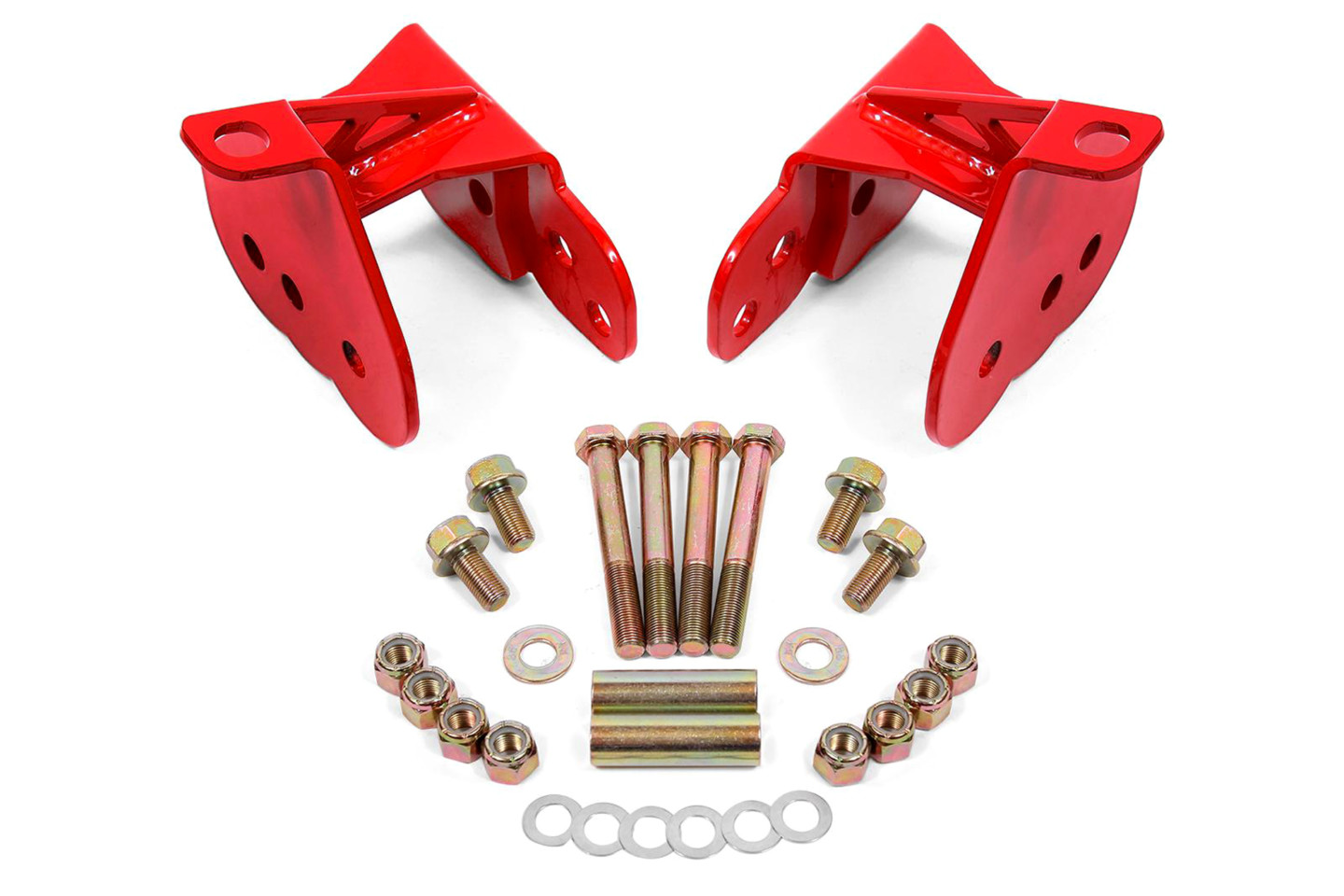

What helps make these Control Arm Relocation Brackets an easy install is the fact they are bolt-on and no welding is required. The install time suggested by BMR is between two to three hours and the tools needed are pretty simple including: wrenches, sockets, hydraulic jack, jack stands, and a drill with a sharp ½-inch bit. We say “sharp” because we’re always forgetting to grind ours and they seem to take forever to get through any metal.

Available in a durable powdercoat of either Black Hammertone or BMR Red, these are heavy-duty pieces ready for serious muscle with real torque. These BMR Control Arm Relocation Brackets are made from 3/16-inch, laser-cut, and CNC-formed hardened plate steel.

The revised design means there are now three bolt-on locations that prevent any counter-rotation but more importantly the need to weld any part of the bracket to the OEM hardware. BMR does note that for more extreme applications as you start doubling your factory horsepower and beyond that welding is also recommended in addition to the bolt-on assembly.

Available in a durable powdercoat of either Black Hammertone or BMR Red, these BMR Control Arm Relocation Brackets are made from 3/16-inch, laser-cut and CNC-formed plate steel ready for serious muscle with real torque.

The geometry behind this part is fairly simple. What BMR Control Arm Relocation Brackets do is adjust the instant center of where the arms theoretically would intersect further back because the bracket is lower. With the instant center further back, there are more anti-squat characteristics during acceleration.

The lack of squat or sag under a heavy launch will dramatically improve times at the drag strip. The addition of Control Arm Relocation Brackets also translates into faster corner exit speeds on a road course when the pedal is mashed mid-corner. Bottom line is more control and more power is put to the ground in these hefty classic platforms.

Price of the BMR Control Arm Relocation Brackets kit is only $99, which seems like an upgrade that A-Body owners should seriously consider.