The old adage stating no replacement for displacement has been highly contested for years. But, whether you’re a small-block or big-block guy, you have to appreciate this little powerhouse put together by Keith Dorton at Automotive Specialists Racing Engines. “The customer wanted something he could drive, and not be embarrassed at stop lights,” said Keith.

The goal was to produce a streetable engine that could produce 500-plus horsepower and last for a very long time. The build started by using a Dart SHP block as the foundation. The rotating assembly consists of a Molnar crankshaft and 6-inch connecting rods slinging a set of Mahle pistons in the 4-inch-plus bores. Final assembly comes in at 9.7:1. Slapping the valves open and shut is a billet roller cam from Crane Cams.

After the Cometic head gaskets were slid into place, The Air Flow Research Eliminator cylinder heads are dropped onto the block. These heads feature a 195cc intake runner, and 2.05- and 1.60-inch valves. Chamber size comes in at 65cc. A set of 1.5-ratio rocker arms from Crane make sure the valves open and close when they should.

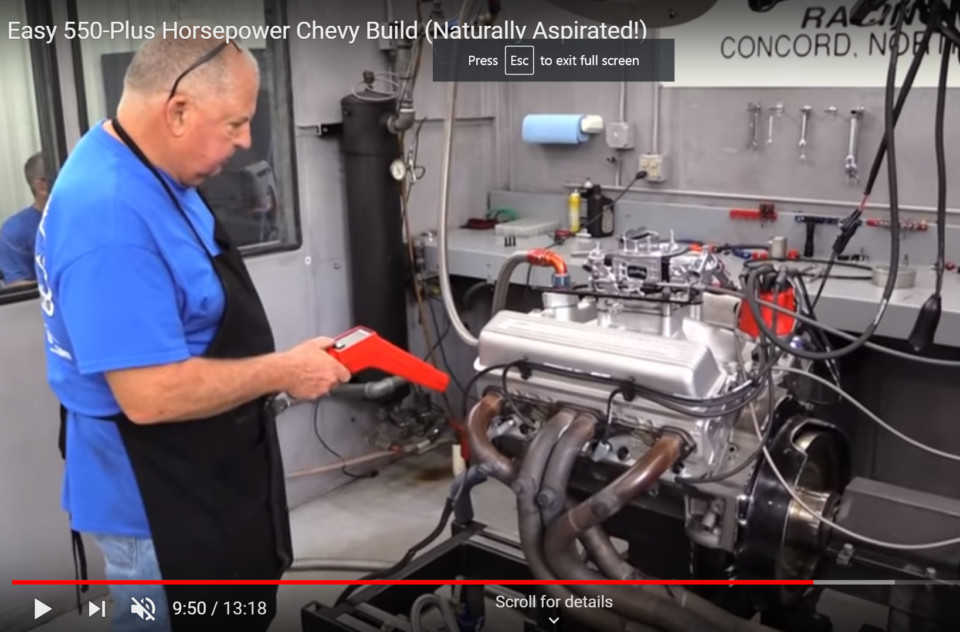

During the dyno testing, an Edelbrock Victor Jr. Intake first supported a 750 cfm Holley Brawler carburetor. After a few dyno runs were made, Dorton swapped the Brawler for an 830 cfm Holley. To say the engine liked the increased cfm is an understatement, but you’ll have to watch the video to see the improvement.

All-in-all, this is a great combination for reliable street duty. What’s more, it’s a simple recipe that you can copy and assemble for your hot-rod Chevy and get the type of engine you can definitely be proud of firing up on a Saturday night.